Even if you’re careful, and use good operating procedures, chances are that sometime you’ll end up with you and your tractor stuck in mud, out in the field, with an implement attached. When this happens, it’s important to take several precautions to help avoid machine damage and personal injury.

When the wheels of your tractor first start to spin, raise your attached implement and engage the differential lock, if the tractor has one. If the wet area is small and you can make it through without serious risk of getting your tractor stuck, then continue through the area with the implement raised. Do not stop the tractor in the wet area. More traction is required.

If you don’t think you can go through, stop the tractor, engage the differential lock, if the tractor has one, and raise the implement off of the ground. Next, put the tractor in reverse, and with the throttle about one-fourth open, slowly engage the clutch and try to back out of the wet spot. If this fails, stop. Continuing to spin the rear wheels will dig the tractor in deeper.

If you have tried to back out and failed, try digging the mud away from behind the front and rear wheels. Dig far enough so if you get the tractor moving in reverse, you can continue to back out and build up momentum. Place boards behind the wheels to provide a solid base, and try to back out slowly.

If all of this fails, it’s time to get another tractor to pull you out.

Pulling the stuck tractor free

First, it may be necessary to remove the implement attached to the mired tractor. If so, disconnect any hydraulic lines and make sure they will not be run over or dragged through the mud. Connect a chain to the frame of the implement then slowly pull it from the mud with the second tractor. When pulling an implement in this way, you have limited control over its direction of travel. So move it slowly and carefully. When the implement reaches solid ground, attach the second tractor to it properly and pull the implement out of the way.

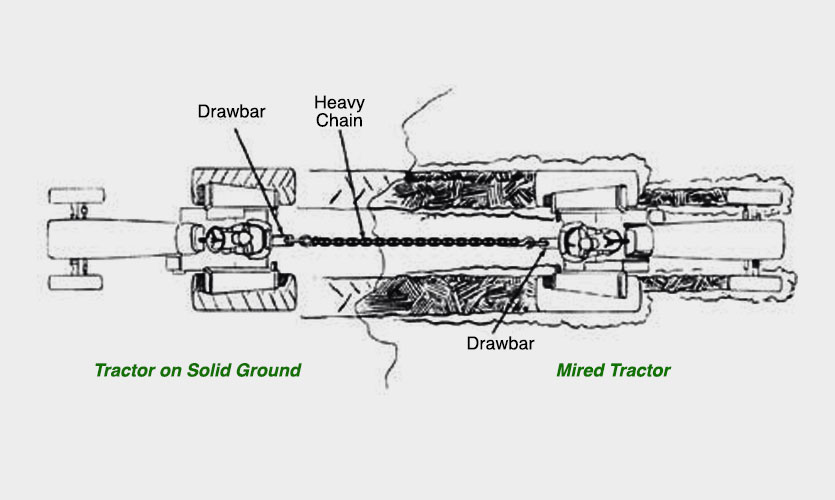

Pull the stuck tractor out backwards if possible. The tractor stuck in the mud has less resistance if it’s pulled out through the same ruts already made. Always keep the pulling tractor on solid ground and use a strong chain or tow bar. Cable is not recommended. Make sure these towing devices are big enough and strong enough to handle the load. Before towing, make sure the area is clear of people and animals.

Hitch the chain from drawbar to drawbar between the tractors. Hitching higher can tip a tractor over backward when power is applied. Believe it or not, a tractor can tip completely over in less than one second. Reaction speeds are seldom quick enough to prevent this. Attaching the tow bar or chain between drawbars helps prevent damage to the either tractor and reduces the possibility of accidents. After the towing device has been pulled tight and the second tractor is pulling, put the stuck tractor in reverse to help build momentum.

After removing a tractor stuck deeply in mud, inspect it thoroughly to make sure it is still in good operating condition. Wheel bolts may have worked loose, or mud may be caked on the engine or other vital areas of the tractor, all of which should be thoroughly cleaned.

And remember, always read the Operator’s Manual before operating any piece of equipment and follow all operating and safety instructions.

Helpful Links: